Monitoring Control System Network Health

Leadership

Posted by: Lord & Company

8 years ago

The Challenge:

New control systems have greater communication requirements than in the past. Tighter regulatory restrictions demand that control data must be passed between areas of the plant. Reduced staffing requires that plant information needs to be accessible anywhere in the plant, or sometimes outside of the plant. Advanced graphical interface tools and data logging place a greater demand on the control system’s communications bandwidth. All this combines to make the communications backbone of a Control System a critical component.

Due to the increased demand for speed and reliability, specially designed industrialized hardware and redundant fiber networks were used. The redundant hardware made sure that any one break in a communication path would not restrict the communications. However, this break needed to be corrected before a second issue occurred. The decision was made to use the computer-based SCADA control system to monitor its own health and alarm if a problem was detected.

Hirschmann’s Rail-Switch family were selected from a variety of vendors providing industrialized, managed Ethernet switches because they supported the Ethernet/IP communication protocols used by the control system and could be integrated directly into the system without the need for additional hardware.

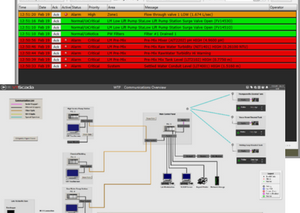

The Trihedral VTScada SCADA application was configured to monitor the health of the network switches. A loss of redundancy would be alarmed on by the computer system in the same place that process alarms (high temperature, low pH, etc.) are handled, providing a visual indication, audible indication, historical log, and remote notification by way of phone, email, or text.

The Solution:

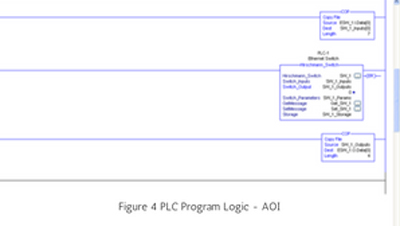

Integrating the switch into the system was a three step process: configuration of the switch, implementing the Hirschmann-provided tools in the Rockwell Automation PLC control system, and configuring the computer-based SCADA software to monitor, display, and log alarm conditions.

Step 1: Configure the Switch

Using Hirschmann’s HiDiscovery software tool, the managed switches were configured for redundant fiber-ring topology. In addition to the basic configuration, each switch was configured to enable the Ethernet/IP protocol and the Signal Contact configured to activate on a loss of Redundancy in the ring.

It is important to note that the HiDiscovery software is provided by Hirschmann with all managed switches. However, the other switch configuration tools like the Web-based interface and the Command Line Interface can also be used.

The EDS (Electronic Device Signature) Files and Rockwell Integration tool were downloaded from the Hirschmann website. The EDS files were added to the Rockwell Software Logix5000 programming software using the EDS Hardware Installation Wizard, allowing the Switch to talk to the PLC processor as if it were an IO module. To establish the communications link between the PLC processor and the switch, the switch was simply added to the Ethernet Network tab as an “IO Module”, specifying only the IP Address of the switch and rate of data exchange.

In order to process the information from the switch, an AOI (Add-on Instruction) developed by Hirschmann was imported into the PLC program. This AOI drives the data transfer between the switch and the control processor, extracting the configuration and status information on the health of the switch directly to the PLC program memory variables.

An instruction was added to the PLC program to check the health of the communications between the PLC and the switch using a GSV instruction to monitor the “Entry Status” and generate a communications alarm.

PLC program logic was created to reference the Hirschmann_Switch AOI in order to manipulate information to/from the switch and populate PLC program variables. Information includes port configurations and status, switch temperature, model & serial numbers, diagnostic statistics, and configuration information. Almost all information available from the switch’s Web or Command Line Interface (CLI) are available.

Finally, tags were created in the VTScada SCADA application to alarm on a loss of communications with the switch, or the loss of redundancy of the fiber ring. When a loss of redundancy occurs, the system will indicate the problem audibly and visually in the alarm summary. Visually, the operator can look at a display showing the entire plant communications and quickly identify the problem and begin the process of fixing the fiber ring.

Conclusion:

Utilizing a Hirschmann industrial Ethernet solution with Rockwell Automation control hardware and Trihedral’s SCADA monitoring software, Lord and Company was able to provide a cost-effective solution to increase the reliability of the customer’s Water Treatment plant control system. By tightly integrating control network diagnostics with the control system located at the plant the system health can be monitored in real-time using tools with which the plant personnel are familiar. This ensures that potential problems are brought to the attention of people who can act on the information in a timely manner, preventing interruptions in the treatment process or loss of data needed for regulatory reporting.

James Ownes

- Customer: City of Reidsville, NC Public Works

- Location: Reid Lake Road, Reidsville, NC

- Description: 9 MGD capacity plant pulling from Lake Reidsville

System Components:

- Rockwell Automation CompactLogix Programmable Controller system

- Hirschmann RS20-0800T1T1SAABHH with Industrial Protocols

- Trihedral VTScada SCADA Software running on industrial computers

Categories:

You May Be Interested In:

Modernize Your Monitoring Equipment With the 2+2(s) Compact Cellular Transceiver

8 years ago by Lord & Company

Reclaim your Time with an HMI Software Hosting Solution: SMS SCADA

8 years ago by Lord & Company

Save Time and Money with an Intelligent SCADA RTU: DRACS-RTU-3100

8 years ago by Lord & Company

Developing Software Tools to Troubleshoot Networks

8 years ago by Lord & Company