Upgrading The Town of Luray, VA’s Wastewater Management System with 2+2(S)

SCADA to the Power of Simple

Challenge:

Upgrading the town of Luray, VA’s wastewater management system to replace obsolete RTUs in the field and improve communication through alarms and alerts.

Solution:

Implementing Lord & Company 2+2s to replace old RTU units and using always-on cellular communication for immediate notifications of issues in the field.

Working with Lord & Company

Lord & Company partners with clients to create and sustain industrial automation systems for operational water and wastewater treatment plants and communication system networks that meet exact design specifications and stringent, evolving EPA regulations. The company’s systems include high-quality components, open-architecture hardware, user-friendly HMIs, useful analysis for all stakeholders, and comprehensive service. Lord & Company’s extensive documentation and available training frees clients from the constraints of proprietary hardware or complicated operations that require specific service.

Overcoming Obsolete Equipment in Luray, VA

The town of Luray, Virginia is located about 90 miles west of Washington D.C. and 45 miles south of Winchester. Originally established in 1812, the town’s growth continues to be fueled by its prime location between rural scenery and travel connections.

The existing wastewater system that supports the town of Luray included RTUs in the field to monitor the health of the system and manage communication of alarms. When the RTUs reached obsolescence, the town needed a new solution that would effectively manage and monitor the system, providing reliable communication while also remaining cost-effective and easy to operate and maintain.

The team from Luray, VA had an existing relationship with Lord & Company, as Lord & Company is responsible for the town’s SCADA systems at the wastewater plant. The Luray team would attend annual training sessions at the Lord & Company offices focused on the hardware and software at their plant. The existing relationship and Lord & Company’s willingness to train Luray’s operational team to effectively maintain and update their systems brought Luray back to Lord & Company for another easy-to-use and maintain solution when they needed to replace the obsolete RTUs.

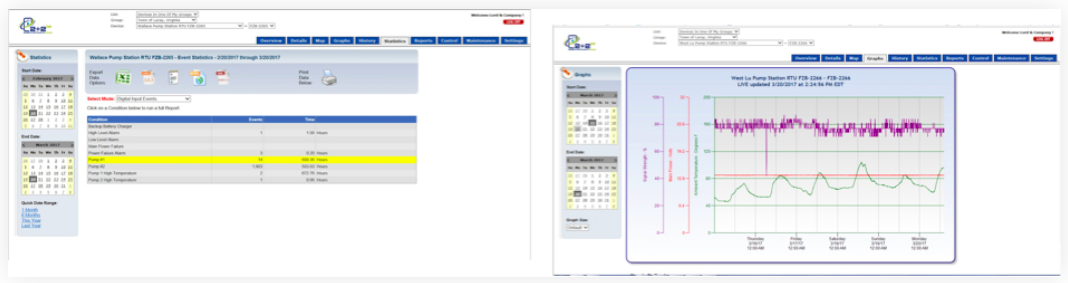

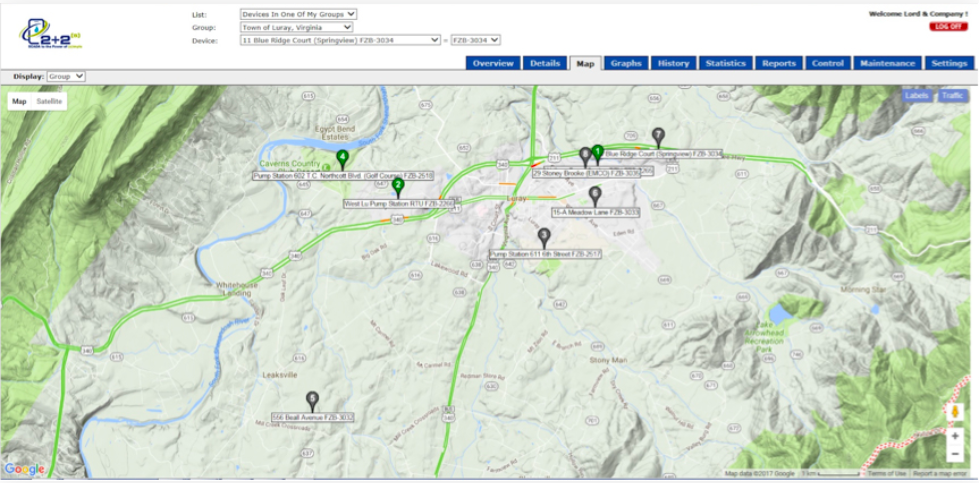

Upgrading RTU Hardware and Vastly Improving Communication

To replace the obsolete RTUs, Luray, VA used Lord & Company 2+2 LC 300s for 8 remote lift stations. The Lord & Company 2+2 product is a compact cellular transceiver for monitoring equipment that sends real-time alarms and status updates via text, email, and an online portal. With the 2+2, Luray, VA operators no longer needed to wait at the office for updates via an auto-dialer, standard on a traditional RTU. Instead, transceivers on the 2+2 use cellular signals to instantly send information. In addition, the system keeps track of on-time and digital input cycles to help when monitoring pump, fan, or compressor run-times and duty cycles and displays all data through an online web portal.

This change in communication method not only alerts management of any failures or notifications immediately, it can also send those messages to a cell phone. The “always-on” experience releases management from the burden of being constantly tied to the office in case of emergency. Cellular service also proved to be more cost effective than the extensive network of phone lines the town maintained for their previous RTUs.

Implementing the System

Luray initially purchased two 2+2 units to test out functionality, and Lord & Company shared a demo of the products as well as the online web portal. Luray then installed the 2+2s at two of their lift stations. After seeing immediate ease of use and success, the town of Luray requested two more units. Lord & Company initially set up and configured the systems with Luray’s specific values – inputs, outputs, and alarm triggers – testing the systems before shipping them the same week they were ordered. Luray was able to receive the 2+2 units, set them up, connect to the web portal, install the needed relays, and then begin using the systems – a straightforward implementation process. The new 2+2 systems monitor factors like pumps runtimes, pump failures, temperature, and power. The 2+2 web portal also provides valuable historical data along with trends and vital statistics.

Achieving Results

The new solution allowed Luray to easily install a configurable system – in the future, they can change the alert notification list on the fly as schedules and responsibilities change in the organization. The cellular capabilities of the new system also greatly reduce cost and provide always-on notifications.

Because the 2+2 systems were so easy to install, Luray saved both time and money installing the systems themselves. Similarly, because the 2+2 system is so user friendly and coupled with extensive documentation, clients like Luray, VA are freed from the constraints of proprietary hardware and their team is able to operate and maintain the system effectively.

Luray plans to replace the remainder of their RTUs with 2+2 systems as the RTUs reach obsolescence.

For more information, read about the Lord & Company 2+2 LC 300s or view a demo.